When it comes to electrical safety, circuit breakers play a crucial role in preventing damage to systems by disconnecting electrical circuits during faults or overloads. One of the most critical aspects of a circuit breaker’s performance is its ability to handle electrical arcs. Arcing occurs when a circuit breaker interrupts current, potentially causing damage to the device, electrical components, or even posing a fire hazard. That’s why understanding how circuit breakers extinguish arcs is essential for ensuring safe, reliable operation.

In this blog, we’ll dive into the key arc extinction principles, common methods, and the specific technologies used by various circuit breakers. By the end of this article, you’ll gain a clear understanding of how arc extinction works and how it helps protect your electrical systems.

What Is Arc Extinction and Why Is It Crucial?

Before diving into the technical aspects, let's first understand what "arc extinction" means and why it's essential.

When a circuit breaker interrupts an electrical circuit, the contacts inside the breaker physically separate. This separation can create an electrical arc — a high-temperature plasma that forms as the current jumps across the gap between the contacts. Arcing can cause significant damage, including:

Erosion of Contacts: The heat generated by the arc wears down the contacts, reducing the lifespan of the breaker.

Insulation Failure: The heat and pressure from arcing can break down the insulation, which might lead to further electrical faults.

Fire and Explosion Hazards: In some extreme cases, the electrical arc can cause fires or explosions, endangering both the equipment and personnel.

Arc extinction is the technology used to prevent these dangers by ensuring that the arc is quickly extinguished. Now, let’s look at how this is achieved.

Common Arc Extinction Methods in Circuit Breakers

Different circuit breakers use various methods to extinguish arcs. Let’s explore the most common techniques.

1. Mechanical Arc Extinction

Mechanical arc extinction relies on devices within the circuit breaker that physically lengthen the arc when the contacts separate. This technique is primarily used in switchgear and is often found in low-voltage circuit breakers.

The idea is simple: as the contacts pull apart, the arc is stretched. The longer the arc, the easier it is to cool and extinguish, as the energy from the arc is spread over a larger area.

2. Magnetic Arc Blowout

Magnetic blowout uses the electromagnetic force generated by a magnetic field to elongate the arc. In this method, a coil is placed in series with the contacts. When the breaker opens, the magnetic field causes the arc to stretch, pulling it into a special arc chamber filled with a solid medium.

The solid medium absorbs the arc’s energy, cooling it down and extinguishing it. Magnetic blowout is commonly used in applications that require high-interrupting capabilities and is suitable for AC systems.

3. Narrow Gap (Longitudinal Gap) Arc Extinction

This method uses the magnetic field created by the arc to stretch it and guide it into a narrow or longitudinal gap. As the arc is forced into this narrow gap, it splits into several smaller arcs. These smaller arcs are then exposed to solid media within the arc chamber, which cools them quickly and extinguishes the arc.

This method is most commonly seen in AC contactors and circuit breakers, offering excellent arc control in low-voltage applications.

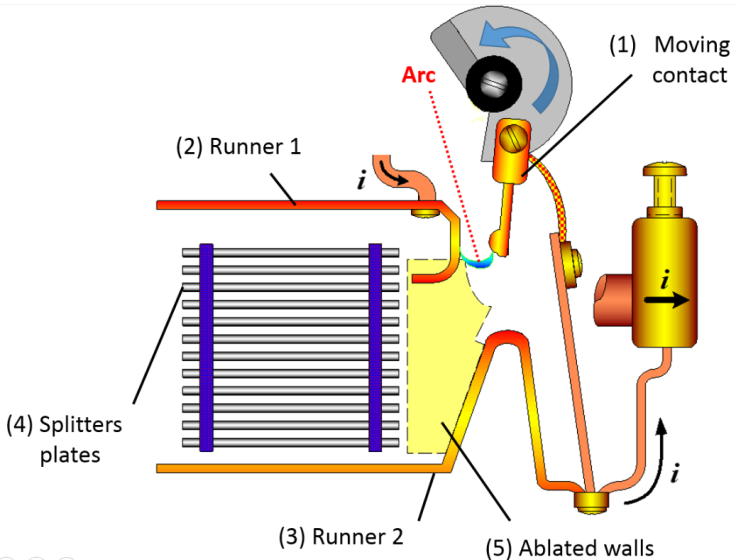

4. Grid Arc Extinction (Metal Grids)

Grid arc extinction, also known as "gridded arc extinction," involves using a set of metal grids positioned in the arc chamber. When the contacts open, the arc is divided into smaller segments by these grids. Each grid acts as an electrode, creating multiple cathode and anode regions that enhance the arc’s breakdown voltage.

This method is often used in low-voltage circuit breakers and offers fast arc extinction due to the enhanced breakdown voltage, especially in AC systems.

Arc Extinction in Specific Circuit Breaker Technologies

Now that we’ve explored the main arc extinction methods, let’s take a look at how these principles apply to various types of circuit breakers.

Vacuum Circuit Breakers: Rapid Arc Extinction

Vacuum circuit breakers (VCBs) operate by using the principle of vacuum arc extinction. When the contacts separate, a high-temperature plasma (arc) forms between them. However, because the circuit is in a vacuum, the arc cannot sustain itself. The lack of ionizable air in the vacuum prevents the arc from continuing, causing it to extinguish rapidly, typically within 10 milliseconds.

VCBs are particularly useful in medium- to high-voltage applications (10kV to 35kV), providing a long lifespan, minimal maintenance, and no risk of explosion or fire due to their inherent safety characteristics. This makes them highly reliable for industrial applications, especially in environments where safety and equipment longevity are paramount.

SF6 Circuit Breakers: Gas-Based Arc Extinction

SF6 (Sulfur Hexafluoride) circuit breakers utilize SF6 gas as the medium for arc extinction. When the circuit breaker opens, the arc is cooled and extinguished by the SF6 gas, which also helps to quench the arc by absorbing the energy.

SF6 breakers are commonly used in high-voltage applications (over 72kV). While they are extremely effective in extinguishing arcs, SF6 gas is a potent greenhouse gas, and environmental concerns about its use have prompted the search for more eco-friendly alternatives.

High-Voltage Dropout Fuse (HRC) Breakers: Simple Arc Extinction

For high-voltage, low-current applications, some fuses (often called HRC fuses) use a simple yet effective method of arc extinction. These fuses contain a small tube of sand or other arc-quenching material that absorbs the energy from the arc. When the fuse blows, the arc is quickly extinguished as the current is passed through the quenching material.

These fuses are typically used in systems where the current isn’t extremely high, and the arc generated is relatively small. The simplicity and cost-effectiveness of these fuses make them ideal for applications such as power distribution.

How to Choose the Right Arc Extinction Technology for Your Application

Choosing the right circuit breaker for your electrical system requires understanding the specific demands of your application. Here are a few factors to consider:

Voltage and Current Ratings: For high-voltage systems, vacuum or SF6 circuit breakers are often preferred due to their superior arc-extinguishing capabilities.

Load Types: Inductive loads, such as motors and transformers, require circuit breakers with higher interrupting capacities because of the larger arcs generated when these loads are disconnected.

Environmental Considerations: Vacuum circuit breakers are ideal for flammable environments as they pose no risk of gas leakage, while SF6 breakers are unsuitable for low temperatures as the gas may liquefy.

Maintenance and Troubleshooting Tips

To ensure your circuit breakers continue to perform effectively, regular maintenance and checks are essential:

Regular Inspection: Check the contacts for signs of erosion or wear, and ensure the arc chamber is free of debris or damage.

Leakage Tests: For SF6 breakers, conduct gas leak tests regularly to ensure no gas has escaped, as this will compromise the breaker’s performance.

Wear and Tear: If the breaker has experienced several high-current interruptions, it may need to be replaced to prevent failure.

Conclusion:

Arc Extinction is Key to Reliable Electrical Protection

In conclusion, the ability to quickly and efficiently extinguish electrical arcs is essential for the safe operation of circuit breakers. Different arc extinction technologies, including mechanical, magnetic blowout, and vacuum-based systems, all have unique advantages depending on the application.

By understanding the principles behind arc extinction and selecting the right circuit breaker for your system, you can ensure your electrical equipment stays protected, minimizing the risks associated with electrical faults and arcing.

For more information or to choose the right circuit breaker for your needs, contact us today — we specialize in providing high-quality, reliable electrical solutions for a wide range of industrial and commercial applications.